- By LiuXing, Senior Flow Measurement Engineer with 15+ years experience in ultrasonic flowmeter R&D,

certified in CFD analysis (ANSYS Fluent Professional)

Structure of Clamp-on Ultrasonic Flow Meter

Structure of Clamp-on Ultrasonic Flow Meter

The clamp-on ultrasonic flow meter belongs to non-invasive flow measurement tools and is widely used in monitoring the flow of various pipeline fluids. Its main advantages lie in that it does not require cutting or modifying the pipeline, thereby reducing installation costs and maintenance difficulty. The ultrasonic clamp on flow meter utilizes the propagation time difference of ultrasonic signals in the fluid to measure flow velocity.

The clamp on flow meter ultrasonic fixes the ultrasonic sensors on the outside of the pipeline through clamps. During design, it is necessary to ensure that the clamps can firmly clamp onto pipelines of different diameters and materials. The sensors usually include a transmitter and a receiver, and their installation positions need to be reasonably configured to optimize the propagation path of ultrasonic signals and measurement accuracy.

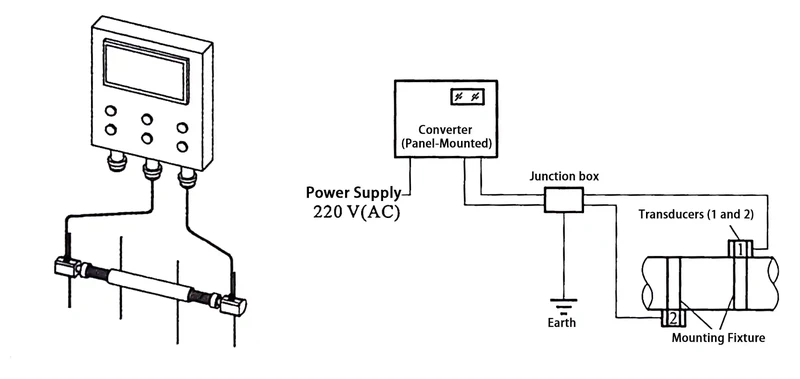

The support and fixing devices of the ultrasonic flow meter clamp on are usually manufactured using corrosion-resistant and high-temperature-resistant materials to adapt to different environmental conditions. In addition, adjustment mechanisms need to be designed to enable precise alignment of the sensors during installation and to adapt to pipelines of different diameters. The sensors should be designed with efficient electrical connections and signal processing systems to ensure accurate transmission and processing of ultrasonic signals. At the same time, continuous optimization of circuit design in aspects such as power consumption and thermal management is required to reduce power consumption and effectively manage the heat generated by the system.The structure of the clamp-on ultrasonic flow meter is shown in Figure 3.5.

Figure 3.5 Structure Diagram of Clamp-on Ultrasonic Flow Meter

The clamp-on ultrasonic flow meter is a type of flow meter. Its detection probes do not need to contact the medium flowing inside the pipeline; they only need to be attached to the outer surface of the pipeline to utilize ultrasonic technology to achieve fluid velocity measurement.

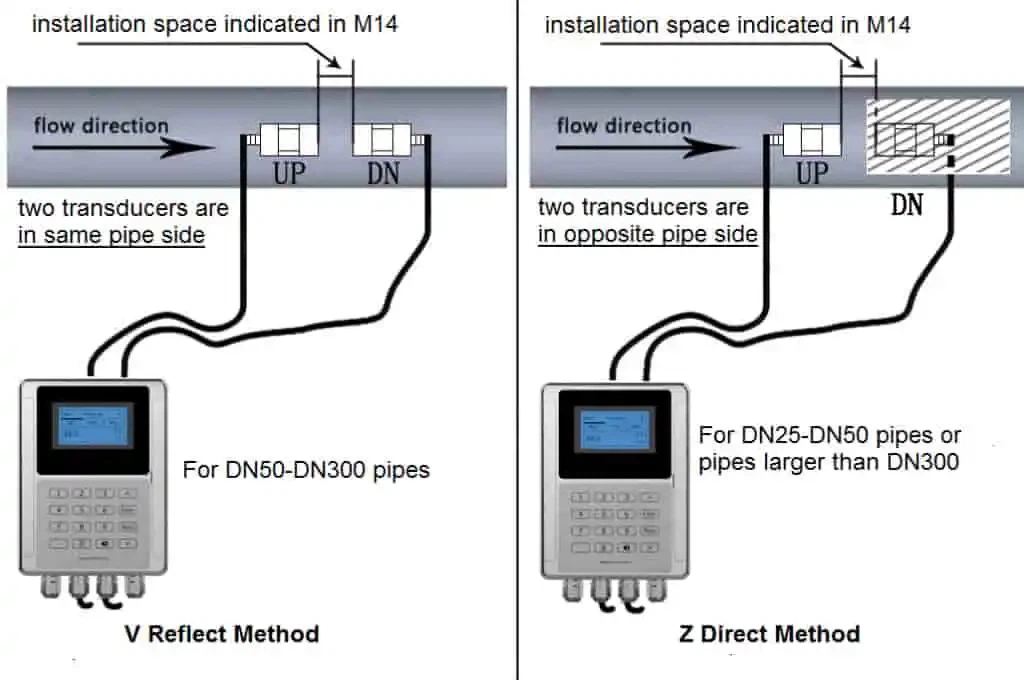

Generally speaking, the standard installation effect method for the ultrasonic clamp on flow meter is the V-method. During installation, the two detection probes are required to be horizontally aligned, and the straight line formed by the two detection probes must be parallel to the pipeline axis. However, since the two detection probes of the clamp on flow meter ultrasonic are separate, when fixing the detection probes on the pipeline, they are usually fixed separately. Therefore, it is often impossible to precisely control whether the straight line formed by the two detection probes is parallel to the axis of the pipeline, which leads to certain errors in the positions of the two detection probes after installation, affecting detection accuracy.

FAQ

Q: What is the difference between V-method and Z-method in clamp-on ultrasonic flow meter installation?

A: The V-method mounts both transducers on the same side of the pipe, with the ultrasonic signal reflecting once off the opposite wall (suitable for small to medium pipes, 20-300 mm diameter, providing stronger signals). The Z-method places transducers on opposite sides, with a direct path across the pipe (used for larger pipes, >100 mm, better for thick-walled or attenuating materials but weaker signals).

Q: How does installation misalignment affect the accuracy of clamp-on ultrasonic flow meters using the V-method?

A: Misalignment in transducer spacing, angle, or parallelism causes path length errors, signal attenuation, and reduced SNR, leading to TOF (time-of-flight) deviations and flow measurement errors of 1-5% or more. Precise alignment is critical for V-method reliability.

Q: What are the key components in the structure of a portable clamp-on ultrasonic flow meter?

A: Main components include paired ultrasonic transducers (transmitter/receiver), mounting clamps or straps, coupling gel for acoustic contact, handheld or wall-mounted transmitter with display, signal processing electronics, and rechargeable battery for portability.

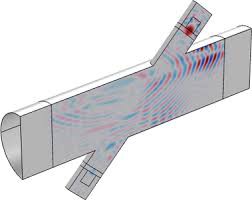

Q: What software is commonly used for acoustic simulation in clamp-on ultrasonic flow meters?

A: COMSOL Multiphysics Acoustics Module is widely used for modeling wave propagation, piezoelectric transducers, fluid-structure coupling, and transit-time simulations in clamp-on ultrasonic flow meters.

Q: What are the advantages of transit-time principle in non-invasive clamp-on ultrasonic flow meters?

A: Transit-time offers high accuracy (±1%) for clean fluids, bidirectional measurement, no moving parts, low maintenance, and works without particles (unlike Doppler, which requires suspended solids/bubbles and has lower accuracy).

Contact our engineering team today for a complimentary feasibility assessment of your pipeline conditions and measurement requirements.